The influence of cutting temperature on cutting effect is analyzed

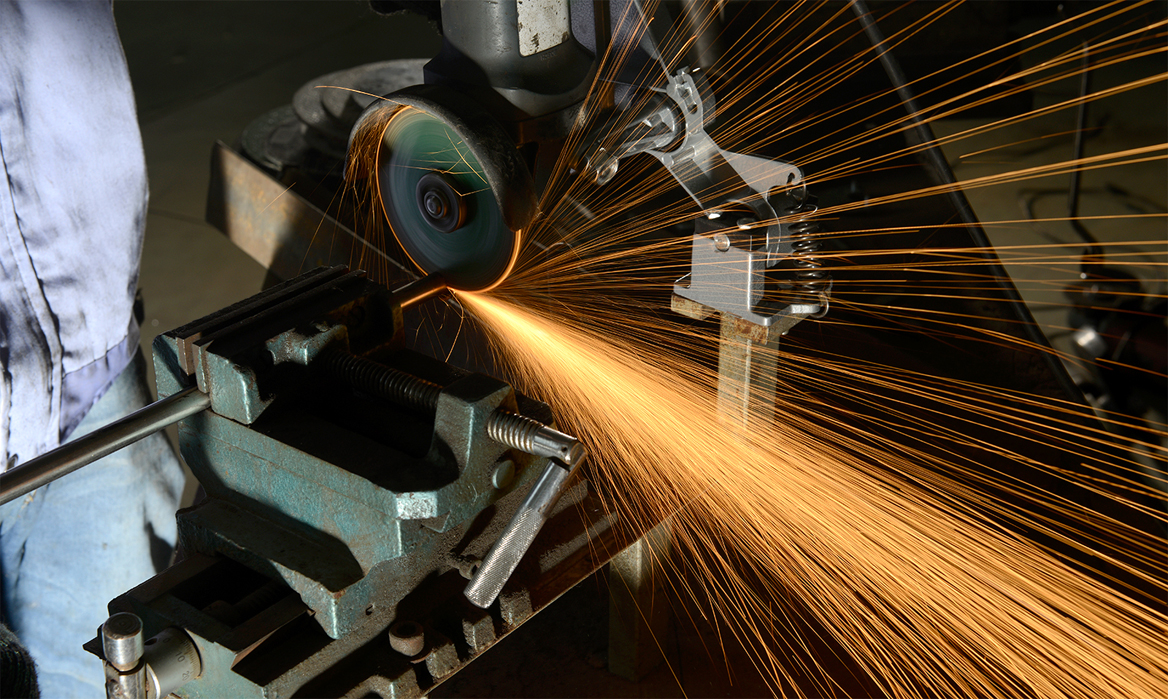

In the daily processing of cutting work pieces, a large amount of cutting heat will soften the surface of work pieces, making it more plastic, conducive to the formation of cutting. However, there are two effects on the work piece. One is the surface quality of the work piece and the other is the machining precision.

The high temperature of cutting will change the metallographic structure of the workpiece surface, which will cause cutting burn. How to avoid surface burns and surface metallographic changes.

It is very important to choose the abrasive tool. The cutting temperature makes the abrasive particles in the grinding wheel bear the temperature stress caused by grinding heat repeatedly during processing, which has adverse effects on the strength and wear resistance of the abrasive particles.

First to know when choosing abrasive machining of the material and hardness of the relevant data such as: cutting hard artifacts should choose the organization loose some grinding tool, because of the high hardness of the material is difficult to cut, grinding grain easy grinding blunt, to maintain the grinding tool from sharpness so choose some soft abrasive. Cutting of poor thermal conductivity material (steel, cemented carbide, etc.) should choose soft grinding wheel, because this kind of material high hardness, low thermal conductivity, the temperature of cutting zone is not easy to disperse, work pieces burn easily, so should choose soft grinding wheel. When cutting nonferrous metal, because of its high chemical activity, it should choose abrasive with good chemical stability for cutting.